Dent Repair Tools by Category

Categories

see allINNOVATION 2024

Go to Trending productsCatalog of Paintless Dent Removal Tools and Accessoires

In our catalog you can find a detailed description of our tool and current prices

We are on YouTube

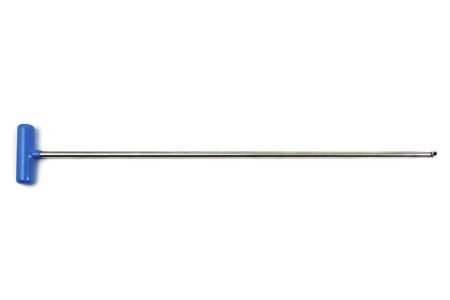

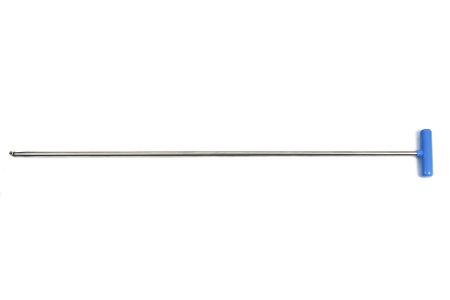

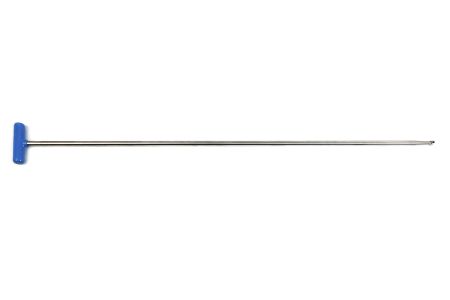

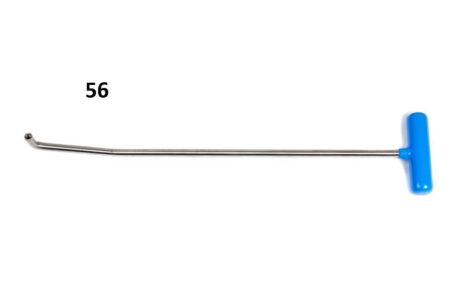

513 Carepoint PDR Rod, Paintless Dent Repair Rod

1.3 thou

We thank everyone who visited us at @mobiletechexpo!

2.9 thou

Let's get ready and load up! See you soon in Orlando, CO

2.5 thou

Follow us on Instagram

In the world of paintless dent removal (PDR), having the right equipment is crucial for achieving professional results, particularly when sourced from the world’s largest supplier of quality tools. In this text, we will explore the basic tools used in paintless dent removal techniques, including their applications in hail damage repair. We will also review leading brands that set the standard in paintless dent repair and provide guidance on selecting equipment for beginners. This will help you not only take your first steps in this craft but also invest in quality PDR tools that deliver excellent results.

Essential PDR Tools for Professional Results

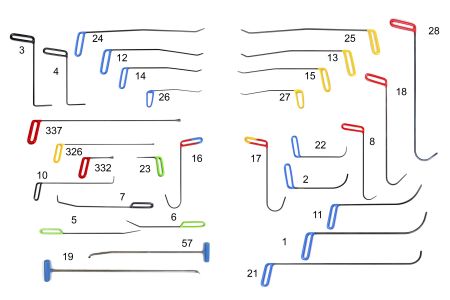

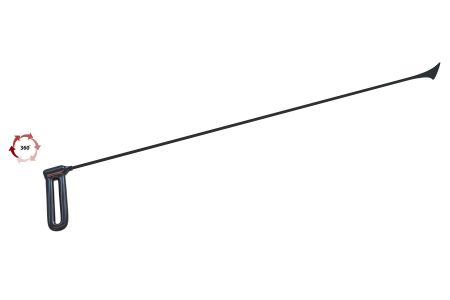

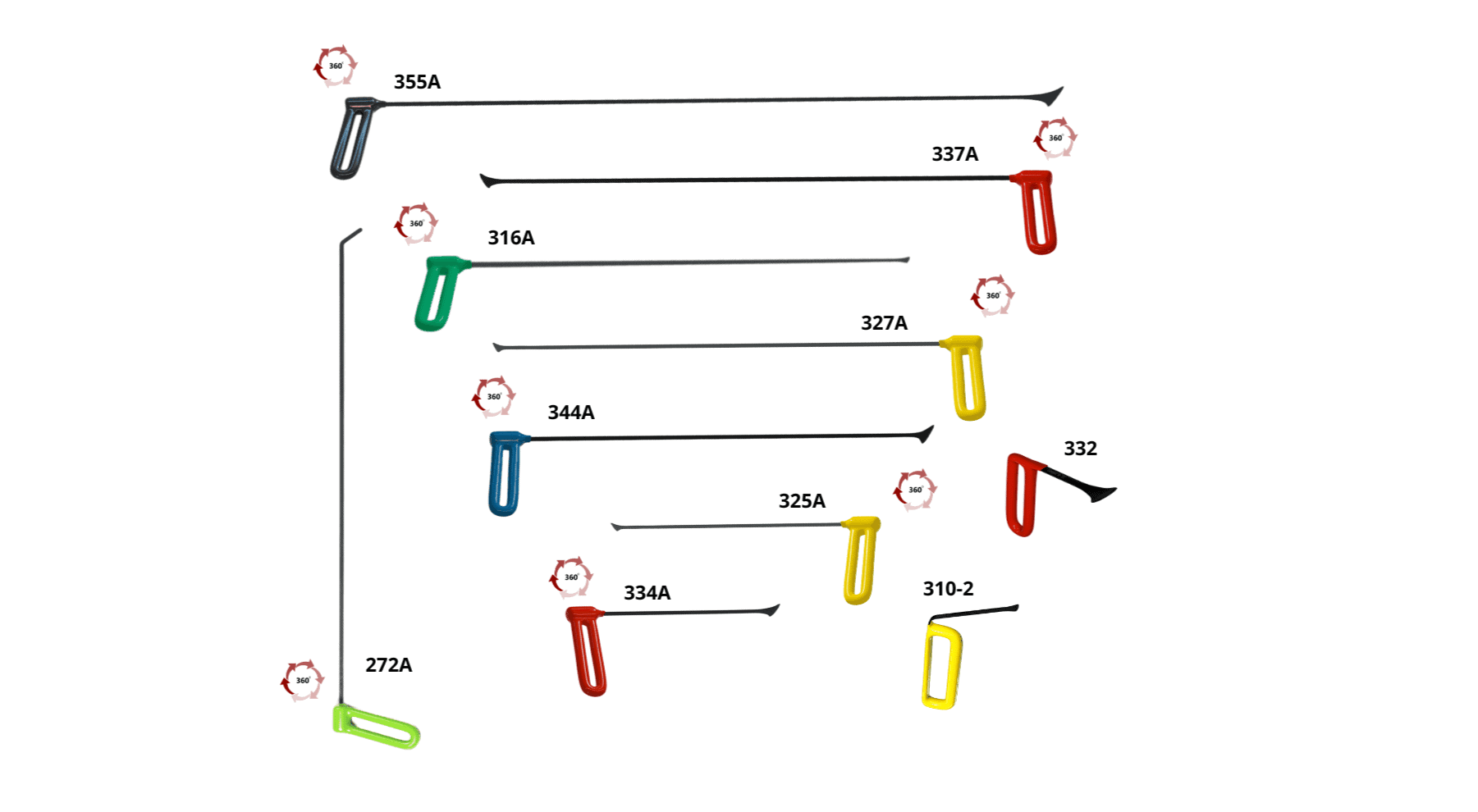

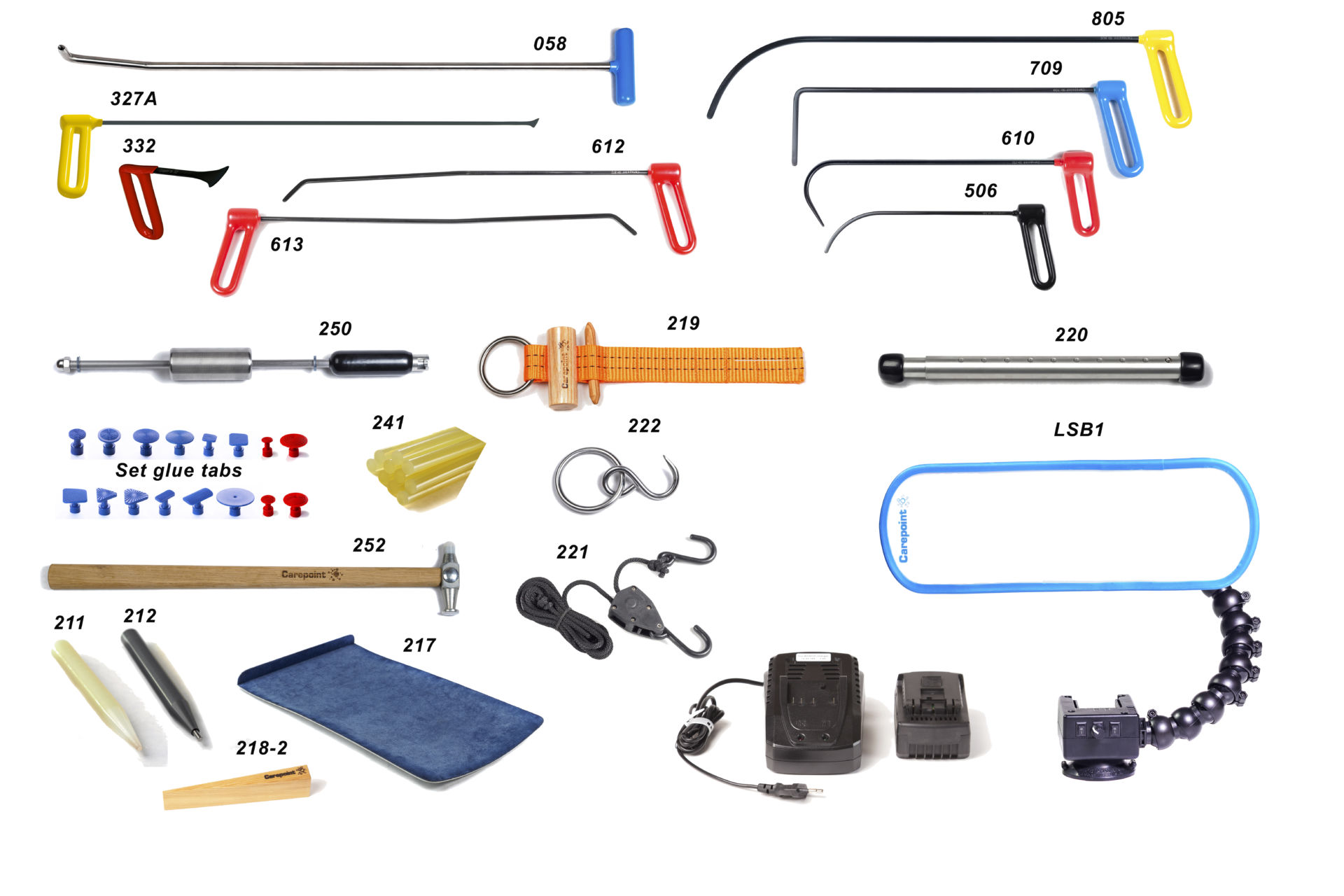

PDR tools come in various shapes and sizes, including paintless dent repair tools, each designed for specific types of damage and vehicle areas. These gears range from simple hand tools to complete sophisticated systems, including rods and cold glue applications. The main purpose of paintless dent removal equipment is to fix damage and restore the car to its original condition. Importantly, this method preserves the car’s original paint and avoids replacing factory parts with new ones. Many top-tier tools come with a warranty, ensuring long-term reliability for professionals.

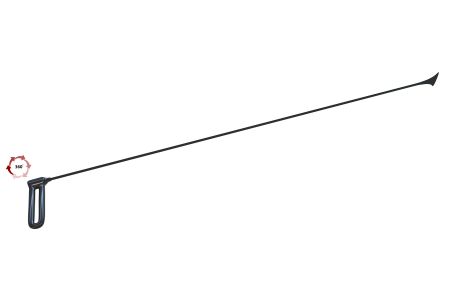

Specialists utilize a range of equipment, including rods, hammers, glue tabs, and paddles. Each item is designed for a specific type of damage or car part — for example, PDR rods are ideal for reaching behind panels, while hammers and knockers smooth the metal surface. There are also various methods for dealing with areas like doors, hoods, or hard-to-reach spots, including cold glue techniques. Sourcing from the largest supplier of quality PDR tools ensures access to a wide array of specialized options.

Precision and professionalism are crucial in this work, especially when using specialized PDR rods. While beginners can use much of this equipment, mastering the paintless dent repair tools takes time. Experts not only develop skills but also learn to choose the right approach and accessory for each task.

Mastering Techniques with Paintless Dent Tools

To effectively use quality Paintless Dent tools, one must develop skills in techniques like pushing, pulling, and tapping to manipulate the metal back into its original shape without damaging the paint.

The pushing technique is essential. Typically performed with rods or chisels, it involves applying controlled pressure from behind the damaged area to reshape the surface. The goal is to make the area smooth, to correct any irregularities using high-quality dent repair tools.

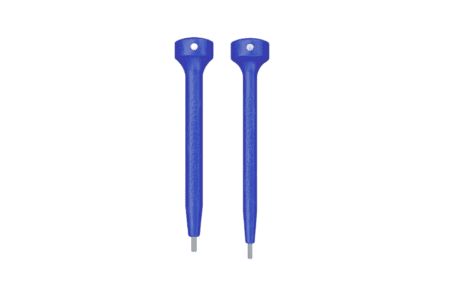

The pulling method is crucial when access to the back is limited. Technicians attach adhesive tabs to the surface and pull it out using tools like hammers or lifters. Proper tab placement and controlled force are key to avoid over-pulling.

Tapping is another vital technique. Specialized hammers or knockers help smooth out minor irregularities after the main work is done. This step requires precision to ensure the surface looks flawless.

Top Paintless Dent Removal Tools Brands in the USA

American companies have long led the development of PDR tools, setting the global standard for quality, durability, and precision in the PDR industry. Among these industry leaders, Carepoint stands out as a brand synonymous with excellence in PDR tools.

Carepoint offers a wide range of products designed to meet the needs of both novice and professional technicians. Each item is designed for comfort and efficiency, ensuring long hours of work with PDR tools paintless dent removal are manageable. The company continuously develops new solutions, including innovative PDR glue, to improve work quality.

Carepoint’s reliability is rooted in the durability of its stainless steel tools. Every item undergoes rigorous testing to ensure it withstands daily use. This makes Carepoint a top choice for professionals seeking dependable tools paintless dent removal equipment.

Carepoint has set the benchmark for excellence, offering technicians the tools they need to achieve outstanding results. Whether you’re a seasoned professional or just starting out, investing in Carepoint’s tools is essential for success.

Choosing the Right PDR Repair Tools for Beginners

Selecting the appropriate PDR tools depends on factors like the type of damage, vehicle make, and your level of expertise. Beginners should start with a simple set for addressing common issues. A good starter kit includes rods, a hammer, knockers, and glue pullers. These versatile items allow you to complete repairs while honing your skills.

When choosing your first set, consider the vehicle parts you’ll work on most often. Research popular car models in your area, as different materials may require distinct approaches. For example, aluminum reacts differently than steel, so understanding these differences is important.

Your experience level also influences your equipment needs. Beginners should start with a comprehensive kit of paintless dent repair tools, while experienced professionals can expand their collection to handle more complex tasks. Starting with a basic but high-quality kit builds a solid foundation without overwhelming you.

Investing in quality tools from Carepoint, even as a beginner, can significantly impact your success in the PDR industry. Durable, easy-to-use equipment yields better results, helping you develop into a skilled technician.