Every car owner faces the need to remove dents from their vehicle at some point. Traditional repair in a workshop can be costly and time-consuming, prompting many to consider the possibility of DIY repairs. As a result, car owners are increasingly turning to an alternative repair method known as PDR (Paintless Dent Repair).

The PDR method, particularly when using an adhesive system, offers a quick and effective solution. However, achieving a quality repair requires an understanding of its basics and principles. In this article, we will delve into what the PDR adhesive system is, its advantages, and how you can repair a dent on your car body by yourself.

What is the PDR Glue Pulling System?

The PDR Glue Pulling System is a specialized set of tools and materials used to remove dents from a car’s body. It allows for the restoration of the damaged surface without the need to remove paint or damage the coating. The basic principle of the PDR adhesive system involves applying a special adhesive to the dent and then using tools to gently pull and restore the shape of the surface.

The PDR Glue Pulling System comprises various components: the glue itself, heating devices to warm the adhesive, dispensers for precise application, and a variety of tools to pull the dent and manipulate the surface. Each component plays a crucial role in ensuring that the dent is removed effectively, and the surface is restored to its original condition.

By understanding how each part of the PDR Glue Pulling System works, car owners can confidently perform their own repairs, saving both time and money while maintaining the appearance of their vehicle.

Principles of Operation of the PDR Glue Pulling System

The PDR Glue Pulling System allows you to quickly and safely remove dents from your car without the need for paint or other chemicals. Repair using this method involves several steps: surface preparation, glue application, dent pulling, and correction. In this section, we will analyze each of these stages and explain the principles of PDR repair.

The first stage is the preparation of the car surface. A clean and prepared surface provides better adhesion, which facilitates further dent repair. It also ensures the precise fixation of the tools used for pulling, allowing the technician to carry out the repair accurately and efficiently. Careful surface preparation helps to avoid additional damage to the bodywork and provides long-term protection for the vehicle from corrosion and other problems.

After surface preparation, the technician applies a specialized adhesive to the center of the dent. The fast-drying properties of the adhesive ensure instant curing, which creates a strong bond between the adhesive and the car body. This strong bond allows the technician to pull out the dent effectively, reducing the risk of additional damage.

The next step is to pull out the dent using specialized tools. The technician carefully and gradually restores the shape of the surface, removing the dent without damaging the surrounding areas. This helps preserve the appearance and value of the car, protecting it from future issues.

After the repair is completed, the technician carefully inspects the surface to ensure the result meets expectations. If any other damage remains on the vehicle, localized correction is performed. This final inspection and correction ensure that the repair is thorough and that the car’s bodywork is returned to its original condition.

Advantages of PDR Glue Pulling System over Conventional Repairs

When repairing cars, technicians are always looking for ways to make the process easier and faster. In this context, the PDR Glue Pulling System is a unique solution. But what exactly sets it apart from traditional methods? Let’s delve into the details.

Preservation of the Original Paint

In traditional repair methods that use sanding and painting, the original paint layer is inevitably removed, which can lead to changes in the shade or texture of the bodywork. PDR repairs help to avoid these problems and preserve the car’s original paint finish. This is especially important for cars with factory paintwork, where maintaining the original appearance is crucial to preserving the car’s value and its aesthetic appeal on the road.

For instance, if your car has a small dent on the door from a minor collision, instead of repainting the entire door —which can be costly and time-consuming — PDR Glue Pulling allows for localized repair. This method ensures that the color and texture of the door remain unchanged.

Time Saving

PDR Glue Pulling is a faster and more efficient dent repair method compared to traditional repairs. Standard methods often involve surface preparation, sanding, priming, and painting, which can take several days. In contrast, PDR Glue Pulling can be completed in just a few hours, saving car owners a significant amount of time.

Imagine a situation where a heavy hailstorm has left dents on your car’s roof. A conventional repair could take many days and involve multiple steps, including sanding, painting, and drying. With a PDR Glue Pulling system, these dents can be removed in just a few hours, allowing you to get your car back on the road quickly.

Less Vehicle Destruction

PDR Glue Pulling does not require the removal or disassembly of large parts of the car, making the process less invasive and preserving the structural integrity of the vehicle. Traditional repair methods might necessitate the removal of body panels or trim pieces, increasing the risk of further damage.

Consider a scenario where your car has sustained minor damage to the door from a light collision. Traditional repairs might involve removing the door and replacing it with a new one, significantly raising the final cost of the repair. With a PDR system, there’s no need to replace anything; specialized tools can swiftly remove all the damage.

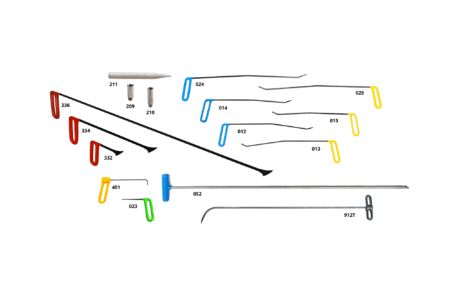

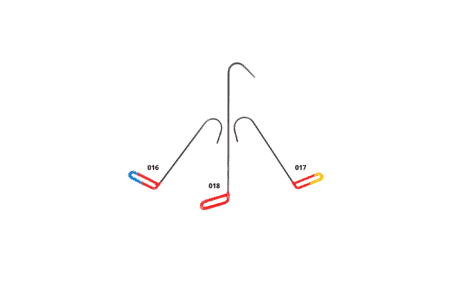

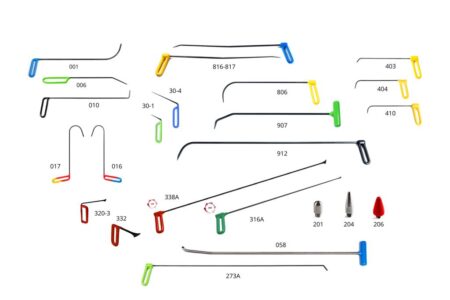

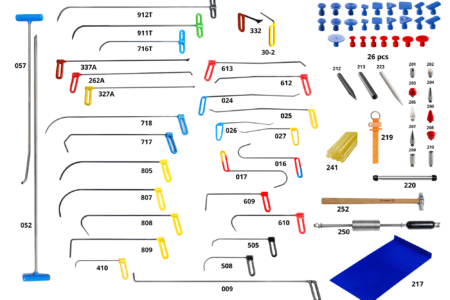

For example, technicians use PDR Whale Tails for door repairs, which allow them to efficiently fix dents and other damage without needing to modify the car. This method preserves the car’s original parts and structure, reducing the risk of additional damage and maintaining the vehicle’s value.

-

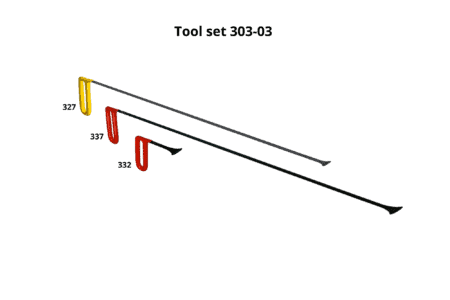

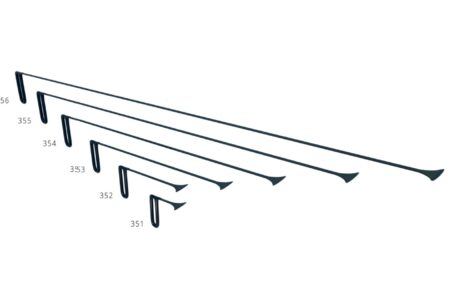

2.0inch / 50mm Whale Tails, FIXED HANDLE RODS, PDR TOOL SETS, Whale Tails rod with fixed handle

Carepoint PDR Tool Set «2 inc 50 ММ WHALE TAIL BLACK»

2.0inch / 50mm Whale Tails, FIXED HANDLE RODS, PDR TOOL SETS, Whale Tails rod with fixed handleCarepoint PDR Tool Set «2 inc 50 ММ WHALE TAIL BLACK»

0 out of 5(0)SKU: n/a -

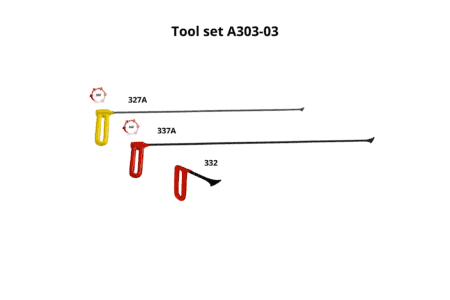

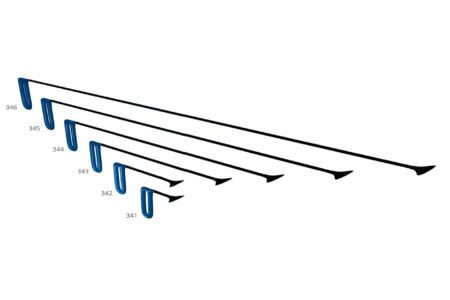

1.6inch / 40mm Whale Tails, FIXED HANDLE RODS, PDR TOOL SETS, Whale Tails rod with fixed handle

Carepoint PDR Tool Set «1.6 inc 40 ММ WHALE TAIL BLUE»

1.6inch / 40mm Whale Tails, FIXED HANDLE RODS, PDR TOOL SETS, Whale Tails rod with fixed handleCarepoint PDR Tool Set «1.6 inc 40 ММ WHALE TAIL BLUE»

0 out of 5(0)SKU: n/a -

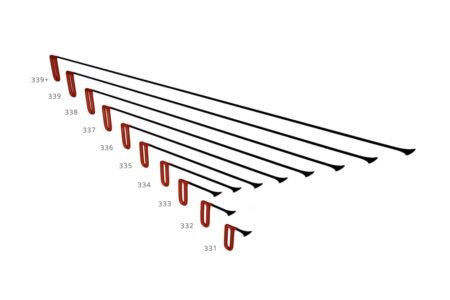

1.2inch / 30mm Whale Tails, FIXED HANDLE RODS, PDR TOOL SETS, Whale Tails rod with fixed handle

Carepoint PDR Tool Set «1.2 inch 30 ММ WHALE TAIL RED»

1.2inch / 30mm Whale Tails, FIXED HANDLE RODS, PDR TOOL SETS, Whale Tails rod with fixed handleCarepoint PDR Tool Set «1.2 inch 30 ММ WHALE TAIL RED»

0 out of 5(0)SKU: n/a -

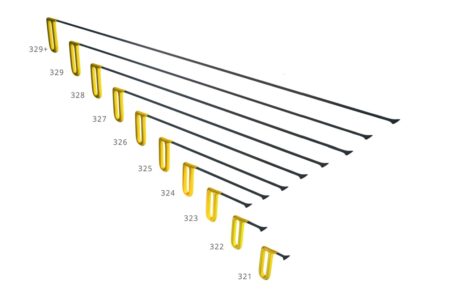

0.8inch / 20mm Whale Tails, FIXED HANDLE RODS, PDR TOOL SETS, Whale Tails rod with fixed handle

Carepoint PDR Tool Set «0.8 inch 20 ММ WHALE TAIL YELLOW»

0.8inch / 20mm Whale Tails, FIXED HANDLE RODS, PDR TOOL SETS, Whale Tails rod with fixed handleCarepoint PDR Tool Set «0.8 inch 20 ММ WHALE TAIL YELLOW»

0 out of 5(0)SKU: n/a -

0.5inch / 12mm Whale Tails, FIXED HANDLE RODS, PDR TOOL SETS, Whale Tails rod with fixed handle

Carepoint PDR Tool Set «0.5 inch 12 ММ WHALE TAIL GREEN»

0.5inch / 12mm Whale Tails, FIXED HANDLE RODS, PDR TOOL SETS, Whale Tails rod with fixed handleCarepoint PDR Tool Set «0.5 inch 12 ММ WHALE TAIL GREEN»

0 out of 5(0)SKU: n/a -

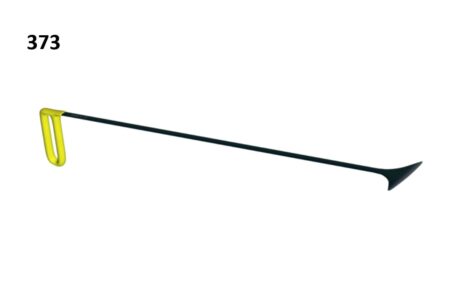

2.8inch-70mm, FIXED HANDLE RODS, Whale Tails rod with fixed handle

PDR Whale Tails Tip Width–70mm/2,8″, L-600mm/23,6″ Carepoint 373

2.8inch-70mm, FIXED HANDLE RODS, Whale Tails rod with fixed handlePDR Whale Tails Tip Width–70mm/2,8″, L-600mm/23,6″ Carepoint 373

0 out of 5(0)Paintless Dent Repair Whale Tails 373

SKU: 373 -

2.8inch-70mm, FIXED HANDLE RODS, Whale Tails rod with fixed handle

PDR Whale Tails Tip Width–70mm/2,8″, L-300mm/11,8″ Carepoint 372

2.8inch-70mm, FIXED HANDLE RODS, Whale Tails rod with fixed handlePDR Whale Tails Tip Width–70mm/2,8″, L-300mm/11,8″ Carepoint 372

0 out of 5(0)Paintless Dent Repair Whale Tails 372

SKU: 372 -

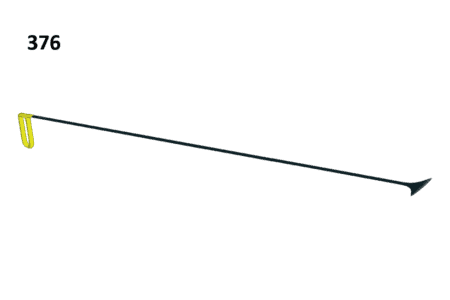

2.8inch-70mm, FIXED HANDLE RODS, Whale Tails rod with fixed handle

PDR Whale Tails Tip Width–70mm/2,8″, L-1500mm/59″ Carepoint 376

2.8inch-70mm, FIXED HANDLE RODS, Whale Tails rod with fixed handlePDR Whale Tails Tip Width–70mm/2,8″, L-1500mm/59″ Carepoint 376

0 out of 5(0)Paintless Dent Repair Whale Tails 376

SKU: 376 -

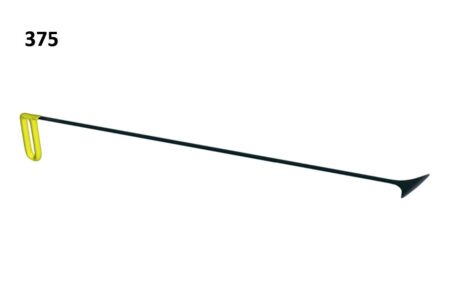

2.8inch-70mm, FIXED HANDLE RODS, Whale Tails rod with fixed handle

PDR Whale Tails Tip Width–70mm/2,8″, L-1200mm/47,2″ Carepoint 375

2.8inch-70mm, FIXED HANDLE RODS, Whale Tails rod with fixed handlePDR Whale Tails Tip Width–70mm/2,8″, L-1200mm/47,2″ Carepoint 375

0 out of 5(0)Paintless Dent Repair Whale Tails 375

SKU: 375 -

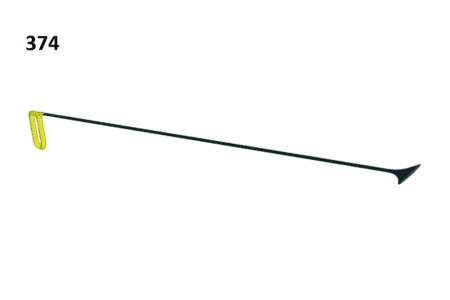

2.8inch-70mm, FIXED HANDLE RODS, Whale Tails rod with fixed handle

PDR Whale Tails Tip Width–70mm/2,8″, L-900mm/35,4″ Carepoint 374

2.8inch-70mm, FIXED HANDLE RODS, Whale Tails rod with fixed handlePDR Whale Tails Tip Width–70mm/2,8″, L-900mm/35,4″ Carepoint 374

0 out of 5(0)Paintless Dent Repair Whale Tails 374

SKU: 374 -

2.8inch-70mm, FIXED HANDLE RODS, Whale Tails rod with fixed handle

PDR Whale Tails Tip Width–70mm/2,8″, L-150mm/5,9″ Carepoint 371

2.8inch-70mm, FIXED HANDLE RODS, Whale Tails rod with fixed handlePDR Whale Tails Tip Width–70mm/2,8″, L-150mm/5,9″ Carepoint 371

0 out of 5(0)Paintless Dent Repair Whale Tails 371

SKU: 371 -

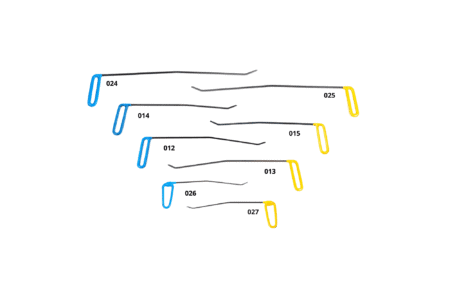

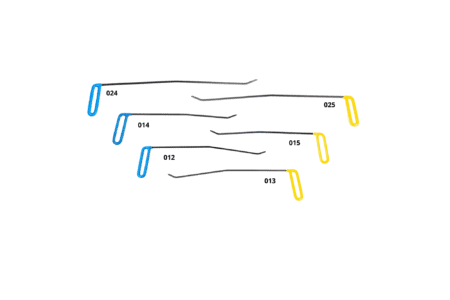

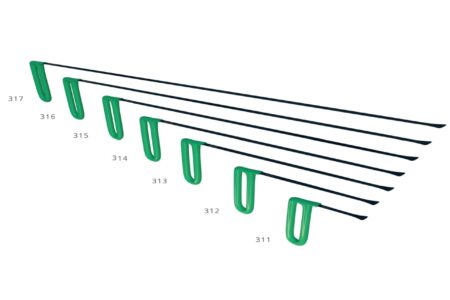

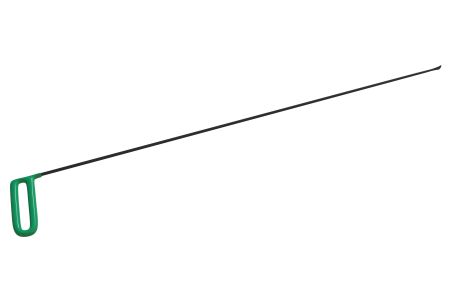

0.5inch / 12mm Whale Tails, FIXED HANDLE RODS, Whale Tails rod with fixed handle

PDR Whale tail with fixed handle Width-12mm/0,5″, L-700mm/27,5″ Carepoint 317

0.5inch / 12mm Whale Tails, FIXED HANDLE RODS, Whale Tails rod with fixed handlePDR Whale tail with fixed handle Width-12mm/0,5″, L-700mm/27,5″ Carepoint 317

0 out of 5(0)Paintless Dent Repair Whale tail with fixed handle 317

SKU: 317

Affordable Materials and Equipment

The PDR Glue Pulling System requires a minimal set of materials and tools, making it more accessible and cost-effective for workshops and auto body shops. Traditional repair methods often necessitate more expensive equipment, materials, and specialized skills.

Workshops that specialize in PDR Glue Pulling can offer more affordable prices for their services because they don’t need costly equipment and materials for the repair. This cost efficiency makes PDR Glue Pulling more attractive to customers who are looking for high-quality, yet affordable, repair options.

Reliable and easy to use, these tools provide high-quality results while maintaining the original condition of the bodywork. Equip your shop with the best PDR equipment and trust your repairs to the professionals!

How to Choose a PDR Glue Pulling System for Repair

Choosing the right Paintless Dent Repair (PDR) Glue Pulling System is crucial for effectively repairing dents on automobiles. There is a wide variety of glue pulling systems on the market, each with unique characteristics designed for specific types of dents and surfaces.

Before selecting a specific system, there are several key factors to consider: the type of dent, the surface characteristics of the vehicle, and the preferences and experience of the technician.

Dent Type and Surface Characteristics

When selecting a PDR Glue Pulling System, you need to consider the types of dents you plan to work on and the surface features they are on. Some adhesives are more effective on metal surfaces, while others are better suited for plastic or aluminum surfaces. For instance, deeper dents or dents on aluminum panels typically require a higher-strength adhesive.

Understanding the nature of the dent and the material of the surface helps in selecting an adhesive that will provide optimal results. For example, if you are dealing with a shallow dent on a steel panel, a standard adhesive may suffice. However, for a deep dent on an aluminum door, a high-strength adhesive that can handle the specific properties of aluminum will be more effective.

Glue Characteristics

Each adhesive in a PDR Glue Pulling System has its own unique characteristics, such as bond strength, curing speed, and elasticity. When choosing an adhesive, it’s important to consider the working conditions and requirements of the repair process.

For example, in low-temperature environments, a glue with faster curing properties is preferable to ensure reliable fixation of the dent. Additionally, the elasticity of the adhesive plays a role in how well it can adapt to the contours of the dent and provide a strong bond without breaking.

Selecting the right adhesive with appropriate characteristics ensures high-quality and effective car repair. For example, if you are working in a colder climate, opt for an adhesive that remains pliable and cures quickly, preventing the bond from weakening due to temperature fluctuations.

-

Cold glue and Glue tabs, GLUE SYSTEM, INNOVATION 2024

PDR Сold glue set 3 pcs 20g/0.04lb Carepoint 3554

Cold glue and Glue tabs, GLUE SYSTEM, INNOVATION 2024PDR Сold glue set 3 pcs 20g/0.04lb Carepoint 3554

0 out of 5(0)Paintless Dent Removal Cold Glue 3554

SKU: 3554$140.00 This product has multiple variants. The options may be chosen on the product page -

Carepoint tips for cold glue, Cold glue and Glue tabs, GLUE SYSTEM, INNOVATION 2024, PDR tools for sale, TIPS

PDR hail removal kit 9 pcs Carepoint 3528

-

Carepoint tips for cold glue, Cold glue and Glue tabs, GLUE SYSTEM, INNOVATION 2024, PDR tools for sale, TIPS

PDR hail removal kit 7 pcs Carepoint 3527

-

Carepoint tips for cold glue, Cold glue and Glue tabs, GLUE SYSTEM, INNOVATION 2024, PDR tools for sale, TIPS

PDR hail removal kit 5 pcs Carepoint 3526

Manufacturer’s Recommendations

It is important to follow the manufacturer’s recommendations and instructions for a particular glue pulling system. Manufacturers often provide detailed information about their products, including recommendations for choosing an adhesive for different types of dents and surfaces. They may also provide guidelines regarding the application and storage conditions for the adhesive. Adhering to these recommendations ensures optimal performance and longevity of the repair.

Practical Experience and Training

Your level of practical experience is another critical factor when selecting a PDR Glue Pulling System. Some adhesives are designed for easy and quick application, making them ideal for beginners or technicians with limited experience. These adhesives typically have broader applications and can easily handle a variety of different types of dents and surfaces.

However, more advanced and specialized adhesives may require a more experienced approach and a thorough understanding of their characteristics and application. These adhesives are usually designed to handle more complex repairs or special types of surfaces, such as aluminum or composites. For instance, a high-strength adhesive designed for deep dents on aluminum panels might require specific techniques and tools that an experienced technician would be familiar with.

How to work with PDR Glue Pulling System: step-by-step instructions

This guide outlines the fundamental steps involved in using the PDR Glue Pulling System, from preparing the surface to completing the final touches. With the right knowledge and skills, you can achieve effective and high-quality dent repairs while maintaining your car’s original condition.

Step 1: Choosing the right adhesive and dispenser

Selecting the correct adhesive is crucial for a successful repair. Begin by assessing the type of damage, the size of the dent, and the specific characteristics of your vehicle. For minor dents, opt for a lightweight adhesive with low viscosity that offers sufficient bonding strength without causing damage to the bodywork. For larger or deeper dents, choose stronger adhesives that provide secure adhesion. Once you’ve picked the appropriate adhesive, load it into the dispenser and prepare it for application according to the manufacturer’s guidelines.

Step 2: Applying the adhesive to the dent

This step requires careful attention to detail. Use the dispenser to apply a small amount of glue to the center of the dent. Ensure the adhesive covers the entire surface of the dent evenly, avoiding any excess that could complicate the repair process. Allow the adhesive to cure for the recommended time before proceeding to the next step.

To facilitate the pulling process, utilize PDR Glue Tabs. These tabs, crafted from high-quality plastic or metal, are available in various shapes tailored to fit different dent types and car surfaces.

By following these steps diligently, you can effectively utilize the PDR Glue Pulling System to address dents on your vehicle, achieving professional results while preserving its original appearance.

Coated with a special glue, they provide a secure grip on the surface of the dent and allow the technician to pull it out accurately and efficiently. Using PDR Glue Tabs helps make the repair process faster, more efficient and more convenient.

Step 3: Applying the Glide Tool

The glide tool is used to smoothly pull out the dent after the adhesive has been applied. Position it on the edge of the dent and begin gently pulling, gradually increasing the pressure. Move smoothly from the edges towards the center to avoid creating new deformations or damage. This step demands careful attention and skill to achieve optimal results. Therefore, it’s advisable to take your time and work slowly.

Step 4: Inspection and Correction

Once the repair is completed, thoroughly inspect the results. Ensure the dent has been fully removed or significantly reduced compared to its original state after pulling. If you’re not satisfied with the outcome, consider repeating the entire process from the start.

After the visual assessment, conduct a strength and stability test of the repaired area. Gently press around the dent and observe its response. A well-executed repair should provide a robust and stable surface that resists denting or deformation.

Tips and recommendations for working with the PDR Glue Pulling System

Choose the right size of glue tabs. When selecting the size of glue tabs, consider the dimensions and shape of the dent. To determine the appropriate size, measure the diameter of the dent and pick a glue tab slightly larger to ensure it covers the dent’s surface completely and provides a strong grip. For instance, if the dent diameter measures 5 centimeters, we recommend selecting a glue tab with a diameter of 6 or 7 centimeters for optimal results.

Consider temperature conditions. For optimal performance with the PDR Glue Pulling System, it is recommended to maintain ambient temperatures between 18 °C to 27 °C (64 °F to 80 °F). At these temperatures, the adhesive cures effectively and provides a strong bond with the surface. Avoid working in temperatures below 10 °C (50 °F) or above 35 °C (95 °F), as this may adversely affect repair quality due to slowed or accelerated curing of the glue.

Inspect the surface conditions thoroughly. To detect hidden damages or deformations, carefully inspect the entire area surrounding the dent. Use specialized lighting tools and mirrors to examine hard-to-reach areas. If you find that the dent is accompanied by cracks or exposed metal, additional repairs may be necessary beyond the capabilities of the PDR Glue Pulling System. In such cases, it is advisable to consult professionals.

Maintain cleanliness and order in your workspace. Keeping your workspace clean and organized is a crucial aspect of successful dent repair. Cleanse the vehicle’s surface before starting work using specialized cleaners or solvents that do not damage the paint. For removing grease, oils, or other contaminants that could affect adhesive adhesion, use alcohol-based cleaners or isopropyl alcohol-based solutions. Always follow proper usage and safety guidelines when handling chemical substances.

Optimize lighting conditions. Effective lighting plays a pivotal role in achieving high-quality dent repairs. Work in a well-lit environment or utilize additional light sources to enhance visibility during repairs.

Uniform illumination is essential as it helps detect even the smallest defects on the car’s surface and allows for an accurate assessment of repair results.