Removing hail dents with a PDR inductor: pros and cons

In recent years, PDR inductor dent removal methods have become increasingly popular among car owners. With this technology, hail damage can be quickly repaired while maintaining the original paint and appearance.

In this article, we will discuss what PDR repair is and the benefits of this method. We will also analyze how it works and tell you how to remove dents yourself.

What is a paintless dent removal?

Paintless Dent Repair (PDR) is a method of repairing dents on a car body without the use of paint. During PDR, special tools are used to press and massage the damaged panel from behind. As a result, the metal of the dent is pushed outward, restoring its original shape. This allows the body to be repaired while maintaining the original manufacturer’s finish.

PDR is a popular alternative to the traditional paint-based method because it is cheaper and faster. This repair does not require painting and curing, and the entire Paintless Dent Repair process is typically completed within a few hours.

PDR is the ideal repair option for minor damage where the vehicle’s paint is intact. Small dents from collisions or severe weather conditions such as hail, tree limbs and rocks can be repaired. PDR can also be used as the first step in a larger repair process, preparing the damaged panel for repainting and minimizing the use of putty.

How does dent removal with a PDR inductor work?

The process begins by preparing the work area and cleaning the damaged area of dirt and dust. The technician then places an inductor against the outside of the dent. The inductor generates high-frequency electromagnetic fields that heat the metal panel around the dent.

When the metal is heated, it becomes more pliable. As the metal heats up, the repairman uses special tools to gently massage and push the dent from the inside out. This allows the damaged area to be reshaped without disturbing the factory paint.

After the dent is pushed out, the technician inspects the result and makes adjustments to achieve the perfect shape. The body surface is then polished and cleaned to restore its natural luster and protect it from corrosion.

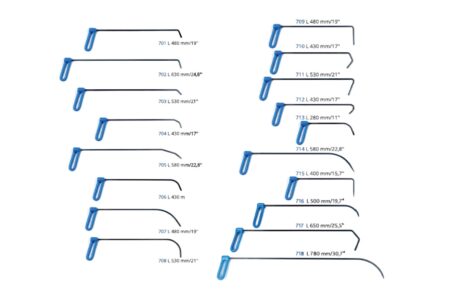

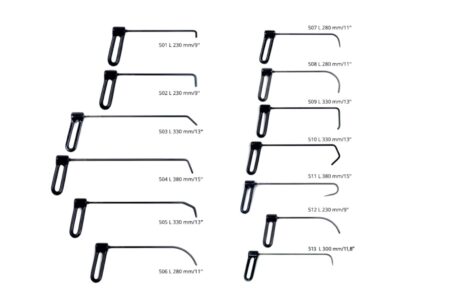

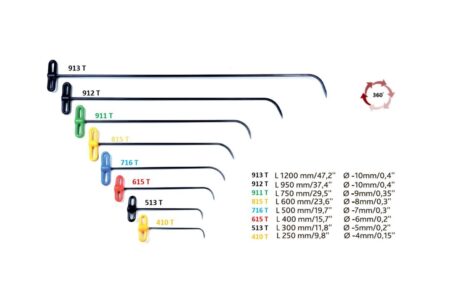

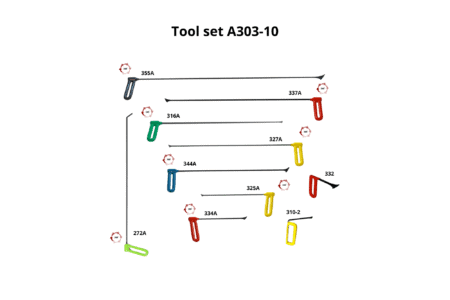

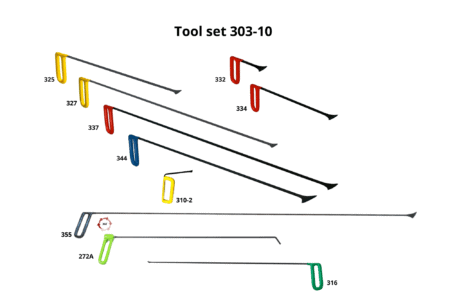

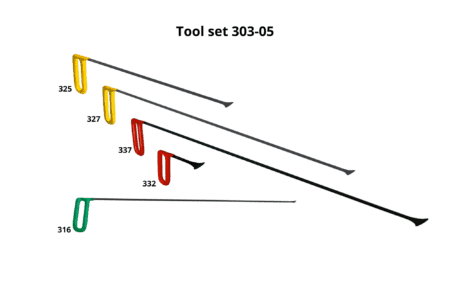

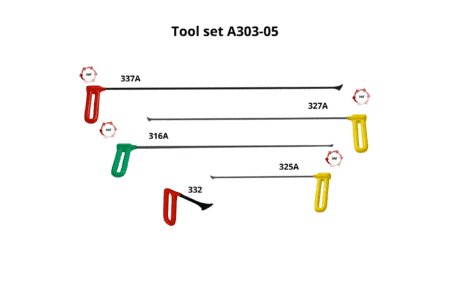

Typically, the PDR Inductor is used with special PDR Rods with adjustable handles. These tools provide optimal access to body dents due to their flexibility and adjustable handles. The adjustable handles allow the technician to adjust the tool to the desired angle and position for more accurate and efficient dent removal.

Such a tool becomes an indispensable assistant when working with a PDR inductor, ensuring professional quality repairs and perfect results.

-

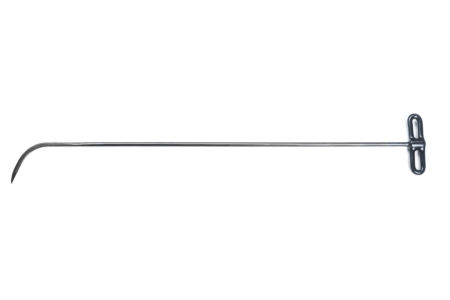

ADJUSTABLE HANDLE RODS, T-handle, ø 0.39inch / 10mm

PDR Rod with adjustable handle ⌀–10mm/0,4″, L-950mm/37,4″ Carepoint 912-T

ADJUSTABLE HANDLE RODS, T-handle, ø 0.39inch / 10mmPDR Rod with adjustable handle ⌀–10mm/0,4″, L-950mm/37,4″ Carepoint 912-T

0 out of 5(0)Paintless Dent Repair Rod with adjustable handle 912-T

SKU: 912-T -

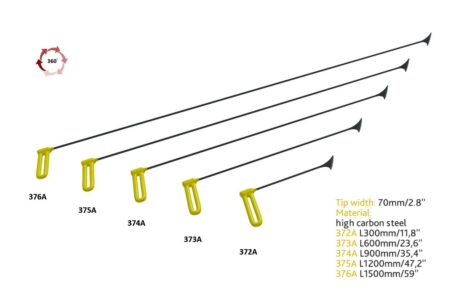

2.8inch / 70 mm, ADJUSTABLE HANDLE RODS, PDR TOOL SETS, Whale Tails ADJUSTABLE HANDLE PDR

Carepoint® PDR Tool Set «2.8 inch 70 ММ Whale tail with adjustable handle YELLOW»

2.8inch / 70 mm, ADJUSTABLE HANDLE RODS, PDR TOOL SETS, Whale Tails ADJUSTABLE HANDLE PDRCarepoint® PDR Tool Set «2.8 inch 70 ММ Whale tail with adjustable handle YELLOW»

0 out of 5(0)SKU: n/a -

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, Rods ø 0.15-0.4 inch / 4-10mm, ø 0,35inch / 9mm

PDR Tool Set «0.35 inch 9 ММ GREEN» rods with adjustable handle Carepoint

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, Rods ø 0.15-0.4 inch / 4-10mm, ø 0,35inch / 9mmPDR Tool Set «0.35 inch 9 ММ GREEN» rods with adjustable handle Carepoint

0 out of 5(0)Paintless Dent Repair Tool Set «0.35 inch 9 ММ GREEN» rods with adjustable handle

SKU: n/a -

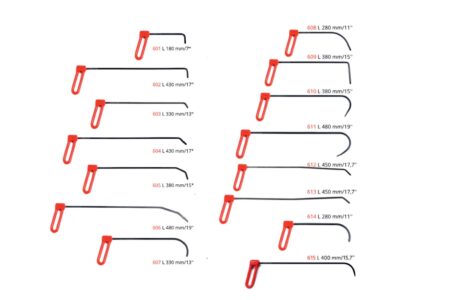

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, Rods ø 0.15-0.4 inch / 4-10mm, ø 0,23inch / 6mm

Carepoint® PDR Tool Set «0.23 inch 6 ММ RED» rods with adjustable handle

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, Rods ø 0.15-0.4 inch / 4-10mm, ø 0,23inch / 6mmCarepoint® PDR Tool Set «0.23 inch 6 ММ RED» rods with adjustable handle

0 out of 5(0)SKU: n/a -

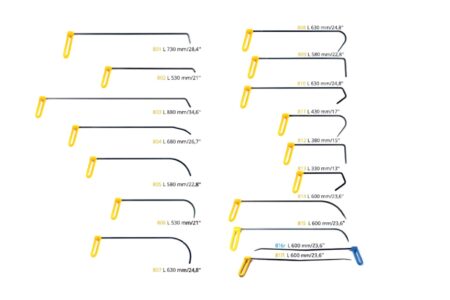

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, Rods ø 0.15-0.4 inch / 4-10mm, ø 0,31inch / 8mm

PDR Tool Set «0.31 inch 8 ММ YELLOW» rods with adjustable handle Carepoint

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, Rods ø 0.15-0.4 inch / 4-10mm, ø 0,31inch / 8mmPDR Tool Set «0.31 inch 8 ММ YELLOW» rods with adjustable handle Carepoint

0 out of 5(0)Paintless Dent Repair Tool Set «0.31 inch 8 ММ YELLOW» rods with adjustable handle

SKU: n/a -

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, Rods ø 0.15-0.4 inch / 4-10mm, ø 0,27inch / 7mm

PDR Tool Set «0.27 inch 7 ММ BLUE» rods with adjustable handle Carepoint

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, Rods ø 0.15-0.4 inch / 4-10mm, ø 0,27inch / 7mmPDR Tool Set «0.27 inch 7 ММ BLUE» rods with adjustable handle Carepoint

0 out of 5(0)Paintless Dent Repair Tool Set «0.27 inch 7 ММ BLUE » rods with adjustable handle

SKU: n/a -

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, PDR tools for sale, Rods ø 0.15-0.4 inch / 4-10mm, ø 0,19inch / 5mm

PDR Tool Set «0.19 inc 5 ММ BLACK» rods with adjustable handle Carepoint

-

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, Rods ø 0.15-0.4 inch / 4-10mm, ø 0.15inch / 4 mm

PDR Tool Set «0.15 inch 4 ММ YELLOW» rods with adjustable handle Carepoint

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, Rods ø 0.15-0.4 inch / 4-10mm, ø 0.15inch / 4 mmPDR Tool Set «0.15 inch 4 ММ YELLOW» rods with adjustable handle Carepoint

0 out of 5(0)Paintless Dent Repair Tool Set «0.15 inch 4 ММ YELLOW» rods with adjustable handle

SKU: n/a -

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, T-handle, ø 0,15inch / 4mm, ø 0.19inch / 5mm, ø 0.23inch / 6mm, ø 0.27inch / 7mm, ø 0.31inch / 8mm, ø 0.35inch / 9mm, ø 0.39inch / 10mm

Carepoint SHARP SET MINI-2 PDR Tool with adjustable T-handle

ADJUSTABLE HANDLE RODS, PDR TOOL SETS, T-handle, ø 0,15inch / 4mm, ø 0.19inch / 5mm, ø 0.23inch / 6mm, ø 0.27inch / 7mm, ø 0.31inch / 8mm, ø 0.35inch / 9mm, ø 0.39inch / 10mmCarepoint SHARP SET MINI-2 PDR Tool with adjustable T-handle

0 out of 5(0)SKU: n/a -

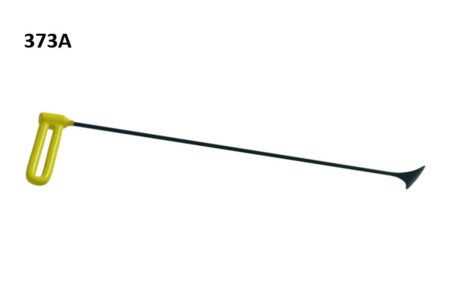

2.8inch / 70 mm, ADJUSTABLE HANDLE RODS, Whale Tails ADJUSTABLE HANDLE PDR

PDR Whale tail with adjustable handle Tip Width–70mm/2,8″, L-600mm/23,6″ Carepoint 373A

2.8inch / 70 mm, ADJUSTABLE HANDLE RODS, Whale Tails ADJUSTABLE HANDLE PDRPDR Whale tail with adjustable handle Tip Width–70mm/2,8″, L-600mm/23,6″ Carepoint 373A

0 out of 5(0)Paintless Dent Repair Whale Tails with adjustable handle 373A

SKU: 373A -

2.8inch / 70 mm, ADJUSTABLE HANDLE RODS, Whale Tails ADJUSTABLE HANDLE PDR

PDR Whale tail with adjustable handle Tip Width–70mm/2,8″, L-300mm/11,8″ Carepoint 372A

2.8inch / 70 mm, ADJUSTABLE HANDLE RODS, Whale Tails ADJUSTABLE HANDLE PDRPDR Whale tail with adjustable handle Tip Width–70mm/2,8″, L-300mm/11,8″ Carepoint 372A

0 out of 5(0)Paintless Dent Repair Whale Tails with adjustable handle 372A

SKU: 372A

Advantages of hail dent removal with PDR

Hail dent removal using Paintless Dent Repair technology is an effective and innovative method of repairing damaged vehicles. PDR offers a number of advantages that make it the preferred choice over traditional dent repair methods. Below we will look at the main benefits of hail dent removal using the PDR process.

Low Cost

One of the main benefits of Paintless Dent Repair is cost effectiveness. Compared to replacing body panels or painting, PDR is much less expensive. This makes it especially attractive to car owners who want to save money on repairs without sacrificing quality.

PDR eliminates the need for complicated and expensive processes such as removing and replacing body panels or using paint and refinish to restore color. The low cost of PDR makes it affordable for a wide range of car owners. This is especially important for those who have experienced minor damage – hail dents or minor scratches – and want to repair them without incurring excessive costs.

Suitable for Retro Car Repair

For many retro car owners, maintaining the original appearance is a top priority. PDR offers the ability to repair dents while preserving the original body panels, eliminating the need to repaint the car.

PDR minimizes the risk of paint damage and keeps valuable car parts in their original condition by eliminating the use of chemical solvents or heavy equipment. PDR is an excellent choice for retro car owners who value authenticity and want to keep their vehicle’s appearance in perfect condition.

Long-term results

One of the key benefits of PDR is its ability to preserve the vehicle’s original body panels and finish. Unlike traditional sanding and repainting methods, which can weaken a vehicle’s protective coating and make it more susceptible to corrosion and oxidation, PDR does not disturb the factory finish.

As a result, the vehicle retains its environmental protection and original appearance for many years. Customers who take advantage of PDR can expect the quality of the repair to be maintained for a long time, saving time and money that could have been spent on regular repairs.

Faster than conventional repairs

PDR offers significant time savings over the traditional repair method. While the traditional method can take days or even weeks, Paintless Dent Repair completes the repair in a matter of hours.

One of the reasons for this speed is that there is no need to repaint. While traditional repair methods involve sanding, painting and polishing, PDR focuses solely on dent repair, minimizing the number of steps.

This makes it an ideal choice for car owners who need a quick and efficient repair. The vehicle is back on the road as soon as possible, reducing downtime and maintaining productivity.

Environmentally friendly

Traditional dent repair methods often involve the use of automotive paints, which can contain toxic substances that are harmful to the car. With PDR, this aspect is eliminated as there is no need to paint the damaged areas. This makes it an attractive choice for those who value the environmental aspects of their car repairs and want to reduce negative impacts.

Disadvantages of hail dent removal with PDR

Paintless Dent Repair (PDR) is an effective and widely used method of dent removal, but it also has its drawbacks. Let’s take a look at the main limitations of this approach.

Not suitable for plastic and composite bumpers

One of the main limitations of Paintless Dent Repair is that it is not always suitable for repairing dents on car bumpers. This is because they are sometimes made of plastic or composite materials that are not suitable for PDR.

Plastic and composite materials are flexible and often have complex internal designs that make it difficult to access the dents and complicate the repair process without damaging the surface or material of the bumper. In addition, bumpers often have stiffeners and other components built into them that make it even more difficult to access the damage and require additional effort to repair.

There is a risk of damage

Paintless Dent Repair (PDR) is generally considered safe and minimizes the risk of body damage, but there is still a small potential for paint damage and further deformation during the repair process. This happens when the dents are close to the edges of the panel or have a complex shape.

Improper use of tools or lack of care can lead to undesirable results such as scratches, scuffs or body distortion that may require additional repairs or repainting. This is why it is important to select qualified and experienced PDR technicians to minimize the risk of damage and ensure quality dent repair.

Difficulties with large dents

While the PDR method can effectively handle small to medium sized dents, repairmen may encounter problems when repairing large dents. Large dents, especially those in hard-to-reach areas, pose serious difficulties for PDR.

Repairing such dents can require additional effort, time and tools, making it less effective and more costly than traditional methods. In addition, when dealing with large dents, there is an increased risk of damage to the bodywork or paint, which should also be considered when choosing a repair method.

How to remove dents with a PDR inductor: Step by Step Guide

In this section, we provide step-by-step instructions on how to use a PDR inductor so you can repair your car yourself.

Successful PDR dent removal requires quality tools. Our tool sets are specially selected sets that include a variety of accessories necessary for a quality repair.

In our range you will find a variety of sets suitable for both beginners and experienced professionals.

Step 1: Connect and Test the PDR Inductor

Before you begin dent removal, you must properly connect and test the PDR inductor to ensure it is working properly. Follow these steps:

Prepare the PDR inductor and its accessories. Make sure you have all the necessary equipment for the job, including the PDR inductor, power cord, and hardware to secure the inductor to the vehicle.

Connect the inductor to the power supply. Plug the inductor’s power cord into a wall outlet or other power source. Make sure that the connection is secure and that there are no problems with the power supply.

Check the operation of the inductor. Turn on the PDR inductor following the manufacturer’s instructions. Verify that it turns on and functions correctly. Check that the elements are heating evenly and without overheating.

Check the cable and connectors. Visually inspect the condition of the cable and connectors for damage or wear. Look for any signs of defects such as cracks or broken parts. If you find any problems, you should replace the damaged components.

Test the heating elements. Check that the inductor heating elements are evenly heated. This can be done by touching them or using a thermometer to check the temperature. In case of uneven heating or overheating, turn off the inductor immediately and perform further testing or maintenance.

Step 2: Set the operating power of the inductor

Once the PDR inductor has been successfully connected and tested, you need to properly set its operating power. Follow these steps to set the optimum operating parameters:

Read the inductor instructions. Read your PDR inductor manual carefully – it contains the manufacturer’s recommendations for setting the power and heating time for different types of dents and body materials.

Select the appropriate power. Determine the power needed for your specific application. This may depend on the depth and size of the dents, as well as the type and thickness of the body. It is generally recommended to start with the minimum power and gradually increase the power to achieve optimum results.

Adjust the power. Follow the manufacturer’s instructions for setting the inductor power. This is usually done with the knob or buttons on the control panel. Increase the power gradually, observing the bump response and the body’s reaction to the heat.

Check the temperature. Monitor body temperature while the inductor is operating. It must not exceed a certain limit to prevent damage to paint or other materials. If overheating occurs, reduce the inductor power or stop heating and allow the body to cool.

Check the efficiency. After setting the operating power, test heat the dent and evaluate the result. If the dent starts to push out or becomes less noticeable, you are on the right track. If necessary, you can adjust the power or continue the heating process until the desired result is achieved.

SPECIAL PDR LAMPS. We also recommend the installation of additional lighting. These lamps will provide bright and even illumination of the working area, which will greatly facilitate the process of detecting and repairing even the smallest damage. Multi-band LED lamps will create a light pattern in the form of a grid on the surface of the car. Such a grid will be an indicator of unevenness and will play the role of guide lines during the repair.

Step 4: Cooling the Dent

Once you have completed the process of using the PDR Inducer to remove the dent, you should move on to cooling the dent:

Prepare a coolant. Use a special coolant, such as a spray or compressed air, to quickly cool the surface of the dent. This will help fix the metal in its new position and prevent it from returning to its previous condition.

Apply coolant. Spray the coolant evenly over the dent. Make sure it is completely covered, and allow it to cool for a few minutes.

Allow the coolant to cool. Allow the coolant to completely cool the metal around the dent. A few minutes is usually sufficient to allow the metal to solidify and lock into its new position.

A special cold glue can be used for this purpose. This will quickly cool the area around the dent, maintaining the shape of the metal and preventing it from deforming.

Check the result. After cooling down, evaluate the dent removal result. If the dent has completely disappeared or is significantly less noticeable, the hail removal procedure with the PDR Inductor can be considered a success.

Repeat if necessary. If the dent is still visible, the PDR inductor application and cooling process can be repeated to further improve the result.

-

Cold glue and Glue tabs, GLUE SYSTEM, INNOVATION 2024

PDR Сold glue set 3 pcs 20g/0.04lb Carepoint 3554

Cold glue and Glue tabs, GLUE SYSTEM, INNOVATION 2024PDR Сold glue set 3 pcs 20g/0.04lb Carepoint 3554

0 out of 5(0)Paintless Dent Removal Cold Glue 3554

SKU: 3554$140.00 This product has multiple variants. The options may be chosen on the product page -

Carepoint tips for cold glue, Cold glue and Glue tabs, GLUE SYSTEM, INNOVATION 2024, PDR tools for sale, TIPS

PDR hail removal kit 9 pcs Carepoint 3528

-

Carepoint tips for cold glue, Cold glue and Glue tabs, GLUE SYSTEM, INNOVATION 2024, PDR tools for sale, TIPS

PDR hail removal kit 7 pcs Carepoint 3527

-

Carepoint tips for cold glue, Cold glue and Glue tabs, GLUE SYSTEM, INNOVATION 2024, PDR tools for sale, TIPS

PDR hail removal kit 5 pcs Carepoint 3526

PDR vs. Traditional Repair: Which is Better?

PDR is ideal for the fast, inexpensive and environmentally friendly repair of small dents, while preserving the factory paint and value of the vehicle.

Traditional repair is more time-consuming and expensive, but offers a high-quality restoration and versatility in dealing with different types of damage. The right choice depends on the size, type and location of the dent, as well as the preferences and financial capabilities of the car owner.